American Barbell SS Comp Barbell Review | Stainless Steel

American Barbell has been around since 1978 and was one of the first companies to create an amazing stainless steel Olympic bar known as the American Barbell SS Comp. It is an absolutely gorgeous bar that really stands out when compared to others in its class.

American Barbell has been on my radar ever since I started up a garage gym. At one point they had a wholesale location here in Austin, Texas, but unfortunately, they closed that location before I was able to visit. I initially purchased their urethane kettlebells, which have a urethane shell and a stainless steel handle. Perfect for anyone who is worried about corrosion and rust, especially garage gym owners.

I reached out to Steven Kendrick of American Barbell to inquire about some products I was interested in reviewing, specifically AB’s high-end barbells. Steven put me in touch with Phil Patti who is the founder of American Barbell. The first conversation I had with Phil lasted over an hour as he schooled me on Barbell design and why he thinks the SS Comp is far and above other Olympic barbells. More on that later.

Phil, by the way, is a technical adviser, designer, and manufacturer for some of the biggest fitness industry brands including (American Barbell, Hammer Strength, Matrix, Technogym, Kabuki, Planet Fitness, Irongrip, Ivanko, Schnell, and probably others). Needless to say, Phil knows his stuff. American Barbell has built over 200K+ Olympic barbells for the commercial fitness industry.

Unboxing

After a few more conversations with Phil and Steve, the SS Comp was on its way.

When the barbell arrived, it came in a long barbell tube typical of what barbells are usually packaged in. It was taped on both ends. After wrestling with the tape, I managed to get the first of 4 end caps off. American Barbell really goes out of their way to make sure the barbells arrive safe and sound.

I have yet to find an easy-to-open barbell tube. You are either fighting with the tape to unravel it or having to get pliers out to try to pull the various end caps off or both.

Pulling out the SS Comp from its tube showed that the sleeves were wrapped nicely and had one last end cap to remove. Needless to say, the bar arrived without issue and looked gorgeous.

American Barbell SS Comp Review

The SS Comp is part of American Barbell’s Olympic Barbell line including the

- Performance Training Bar (uses composite bushings)

- Performance Bearing Bar (hard chromed bar)

- SS Comp Stainless Steel Needle Bearing Bar (stainless steel shaft)

The SS Comp bar utilized the highest standards for barbell manufacturing and boy is it amazing.

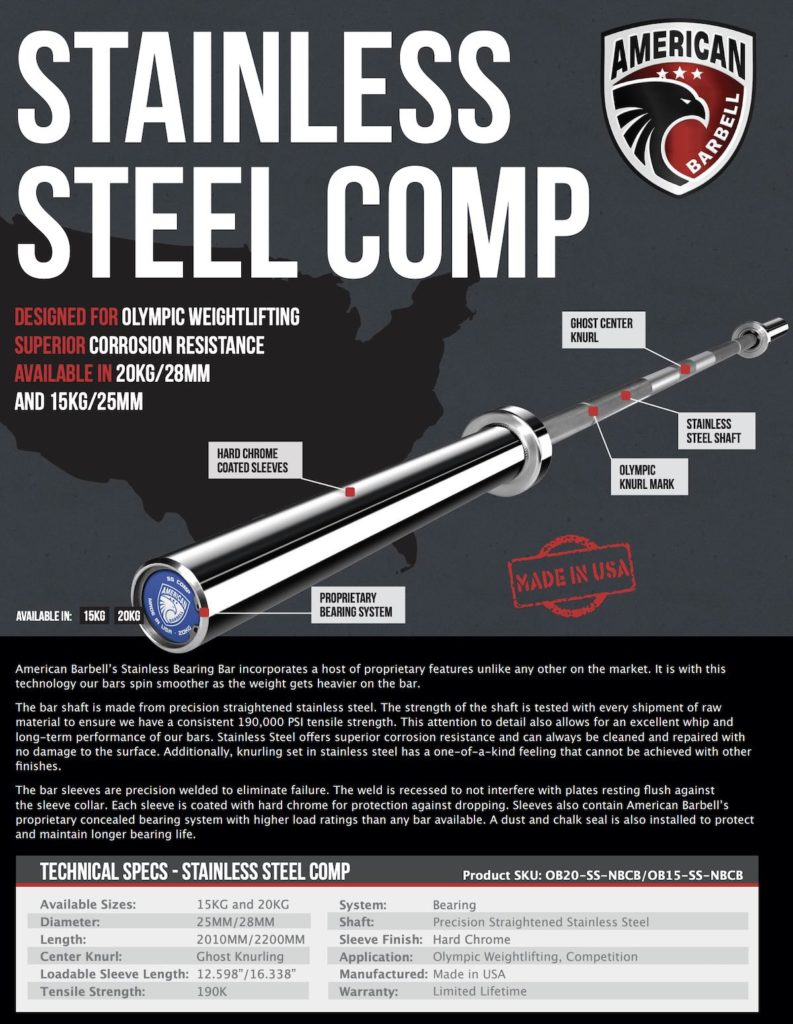

Specifications

- Meets IWF Specifications (Shaft, Diameter, Markings, and Weight)

- Shaft – Precision Straightened Stainless Steel Bar

- Sleeves – Aircraft-Grade Hardened Chrome. Sleeves are smooth without ridges.

- Bearings – Proprietary Needle Bearing System

- Tensile Strength – 190K – Gives a nice whip to the bar.

- Available in IWF specification 20KG 28mm or 15KG 25mm

- Length 2200mm or 2010mm

- Knurl Markings – Olympic Knurl Marks

- Center Kurl is called “Ghost Knurl” – Very lightly etched

- Made in the USA

- Incorporates American Barbell’s own proprietary bearing technology – This provides higher load capacity and smoother rotation with heavier weights. The rotation is smoother and more precisely built.

- Features a protective ring on the inner collar side to keep chalk and dust from penetrating bearings

- Patent No: US D795,971 S

- Warranty: Limited Lifetime

- Price: $795.00 +/- shipping and tax

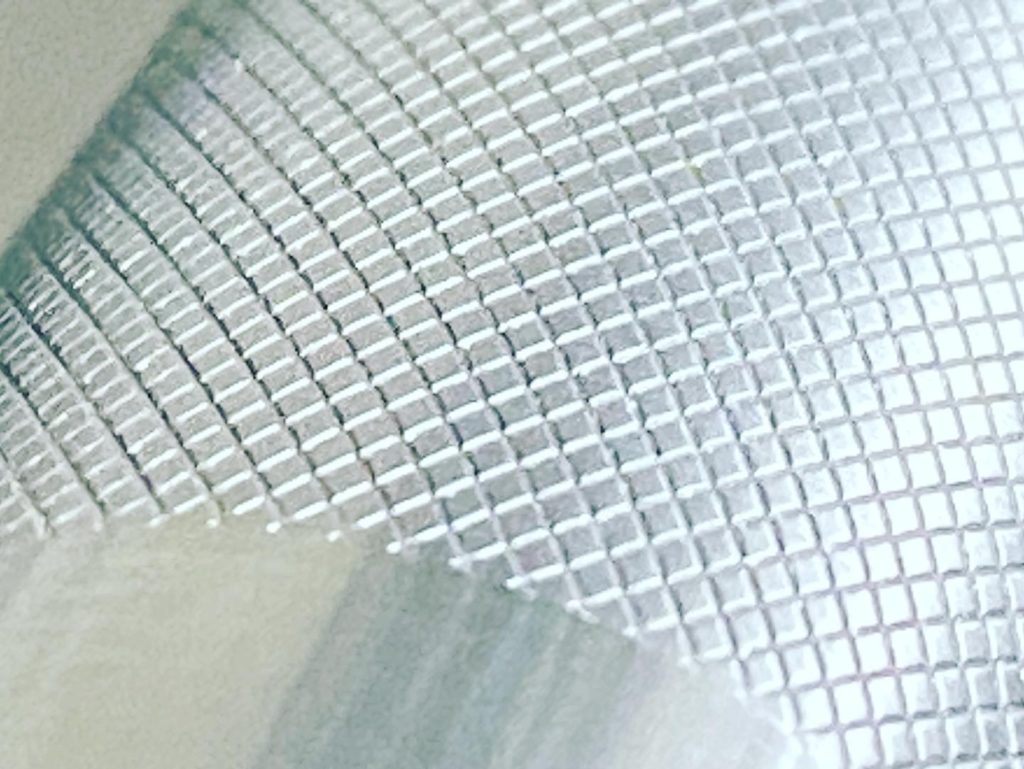

SS Comp Sleeves

It’s rather amazing how UNDERAPPRCIATED this bar actually is. First, there are the sleeves which are coated using aircraft-grade hardened chrome. This isn’t your Harley Davidson conventional decorative chrome, no it’s commercial-grade all the way. The sleeves are also smoothed to a polished finish. The smooth finish takes more time to achieve than the traditional ribbed finish that most barbells come with. Many manufacturers of ribbed sleeves claim their sleeves hold weight better because they are ribbed.

Ribbed sleeves are from fast cheap machining. To say they hold plates on is embarrassing

Phil Patti

American Barbell says that the sleeves have a larger diameter than many of its competitors, which helps prevent weights from shifting and sliding. In any case, I prefer the American Barbell method for one simple reason, it sounds fantastic when sliding the weights on or off. REALLY – sliding the weights on and off is so much nicer on this bar.

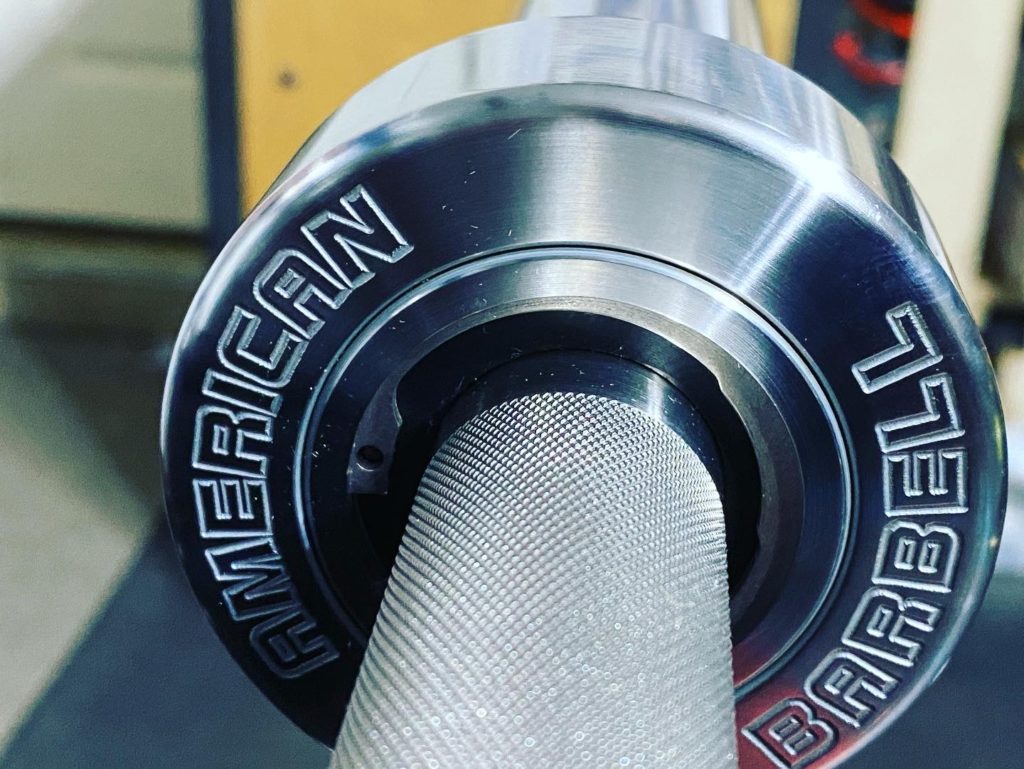

Phil provided some great education on sleeve design. Most manufacturers use what’s called Friction welding to join the “SLEEVE COLLAR” to the “SLEEVE”, making it appear to be one piece. Phil said that his precision welding method is more reliable than friction welding and overtime helps prevent barbell failure. When you get a chance to see the precision welds, you will appreciate what has been done. The look is fantastic. The welds are recessed so that when plates are slid down the sleeve, the plates never touch the welds. Pretty cool. Honestly, the design is so cool, I am really surprised other manufacturers don’t try to imitate it.

The SS Comp is a commercial-grade barbell, meaning it has to be able to stand up to commercial gym use rather than just a home or garage gym. The barbell also meets “IWF” specifications. The IWF (International Weightlifting Federation) is the Olympic weightlifting governing body for Olympic events using barbells.

Friction Welding Vs Precision Welding

Friction Welding

When you look at a barbell sleeve, it’s actually composed of two parts, the sleeve collar, and the sleeve. These two parts are then welded together to form what people refer to as a barbell sleeve. Most manufacturers weld the parts together using a technique called Friction Welding, where the collar is rotated at a high speed and then the sleeve is inserted into the collar by melting the metals together through friction. The two parts are then joined together.

Precision Welding

American Barbell uses a more traditional welding method to join the sleeve and collar together known as precision welding. By doing this, the welds where the metal parts are joined is actually stronger than the steel it’s joined to.

The American Barbell logo is engraved on the inside of the barbell collar, giving it a really nice appearance. AB doesn’t do this on every barbell they sell, but I told Phil it really makes the barbell stand out.

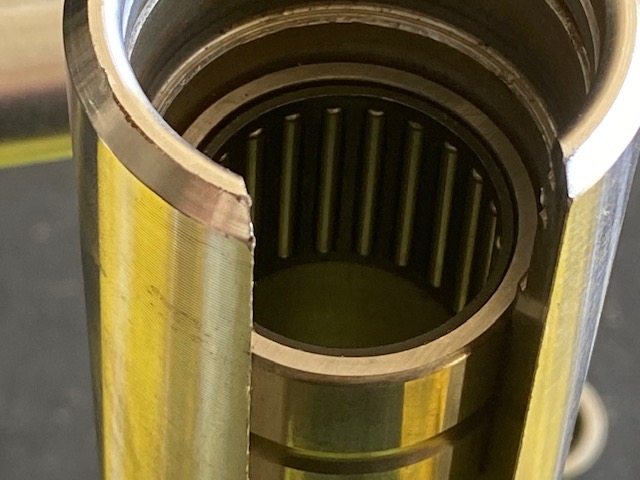

Needle Bearings

Underneath the sleeve is where the magic happens. Most companies that produce bearing bars, don’t appear to know the first thing about needle bearings and how they can damage a bar over time. Most Olympic bars that I have seen have needle bearings touching the bar. With repeated use, these bearings can create pits or wear points, which eventually can turn into stress fractures.

American Barbell designs its needle bearings to have an inner race or sleeve that fits over the bar. In this way, the bearings never touch the bar and prevent the bearings from damaging it. AB also doesn’t skimp on the bearings themselves, they use super precision Needle Bearings that are substantially larger, stronger, and have a higher load rating. Their bearing technology is proprietary, so it can’t be duplicated.

Why Needle Bearings over Bushings?

The more smoothly and reliably a barbell can rotate during an Olympic lift the easier it is for the lifter to have confidence in the barbell. While it is true that the barbell will realistically only move about 180 degrees during the lifting movement, the needle bearings provide a smooth transition over bushings and prevent or at least lessen movements of the plates rotating during the lift.

To make sure the bearings have a longer life span, AB utilizes a protective ring on the inner collar side to keep chalk and dust from penetrating the bearings

28mm and 25mm Grip

Traditionally Olympic bar diameter falls in the range of 28mm – 28.5mm for men and 25mm to 25.5 for women. The smaller diameter bars also have the advantage of making them a bit less stiff and “whippier”. Olympic weight lifters can use the elasticity of the bar to help them during the early stages of the lift. (snatch, power clean, etc). Having a smaller diameter also means it will be easier to grip vs a power bar that usually has a larger grip.

190K Tensile Strength

The Britannica dictionary defines Tensile Strength as the “maximum load that a material can support without fracture when being stretched, divided by the original cross-sectional area of the material. In terms of barbells, Tensile Strength only gives you part of the equation. Another measurement is Yield Strength, giving you the amount of weight a barbell can hold without losing its form.

The formula for Tensile Strength is

σf = Pf/Ao

Where Pf is the load at fracture, Ao is the original cross-sectional area, and σf is the tensile strength, measured in N/m² or pascals.

American Barbell sells a 29mm Power Bar with the same Tensile Strength as the SS Comp. Since the Power Bar has a bigger diameter it should have a higher Yield Strength, so it shouldn’t bend as easily as the SS Comp with the smaller diameter.

Why do companies show off their Tensile strength and not the Yield Strength, which is probably a better representation of the barbell weight capacity? I am not sure.

Knurl

Ah yes, the all-important Knurl.

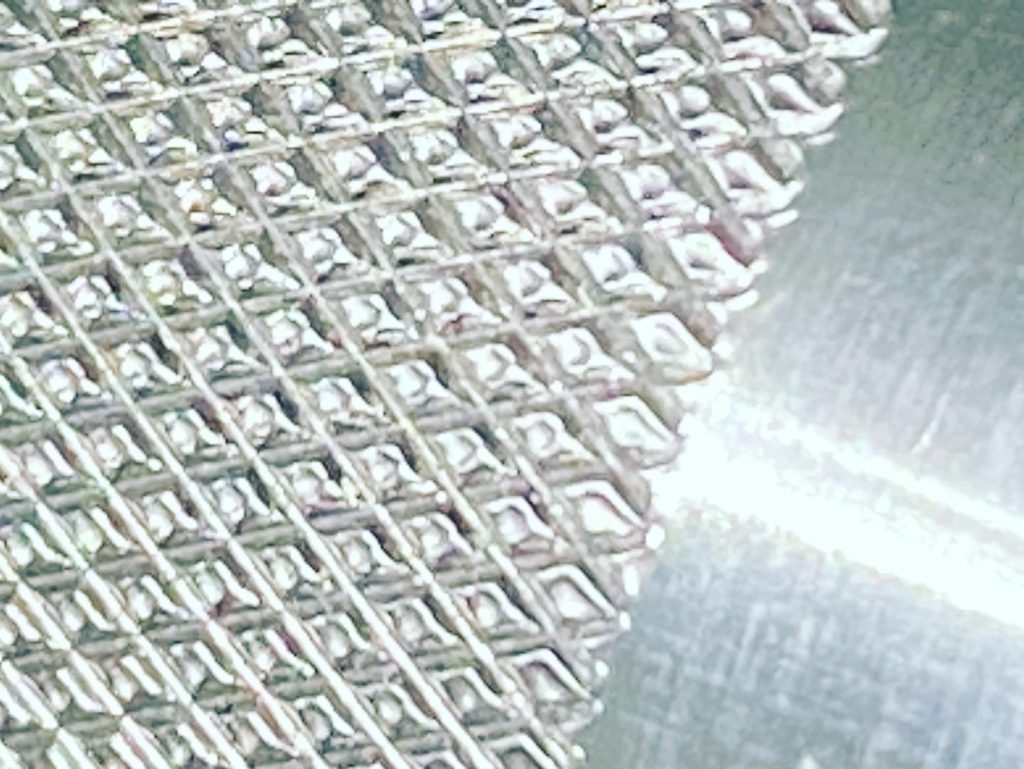

The knurl pattern is considered to be Volcano Knurl but feels much more passive than many Olympic barbells I have used. It feels similar to Hill Knurl IMO, but with slightly more grip. It certainly is much more passive than any power bar I have used. That said, many Olympic lifters want a passive knurl bar so that their hands don’t get chewed up during explosive moves like cleans and AB doesn’t disappoint.

Many non-IWF Olympic bars don’t have a center knurl, because lifters don’t like having a sharp center on the bar passing up the body next to the face. IWF Olympic bars DO have a center knurl because the IWF rule requires it.

The AB SS Comp has what they refer to as “ghost knurl”, which is so light and passive it’s more for looks than grip. It lets you know exactly where the center of the barbell is without actually being a true knurl.

The bar also comes with the standard IWF Olympic knurl markings. I found that the Knurl goes right up to the edge of the Olympic marks without any distortion of grip.

Shaft

I wasn’t exactly sure where to bring up talking about the shaft, but it is exceptional. Being stainless steel means you’re not having to worry about corrosion or rust. AB has taken their Stainless Steel up a notch so that it is actually better than most other manufacture’s stainless steel. Working with metallurgists, AB has come up with a formula for their stainless steel that outperforms typical rust and corrosion standards for that metal type.

With IWF Olympic barbells you have two options, going the more expensive stainless steel route or the less expensive bare steel route. If you go with option 2, you will soon find yourself having to clean the bar on a regular basis to prevent rust from forming. Stainless is much more worry-free.

Competition

As far as competition goes, there are a few companies out there

- Rogue Olympic Weightlifting Bar – stainless steel (Still using bearing on bar technology)

- Eleiko IWF Weightlifting Competition Bar – (steel chromed barbell – Eleiko doesn’t have a stainless steel barbell)

Conclusion

That saying “Buy Once, Cry Once” certainly applies with the SS Comp. While it isn’t the most expensive barbell available, it still comes with a hefty price tag of over $800 after factoring in shipping and tax. For the money though, I am willing to bet that the SS Comp will be really hard to beat in its category and you will find its performance over time much better than others.

The SS Comp ticks all the boxes for those looking for a high-quality barbell that will last a very long time.

Some may find the Knurl a bit too passive for their liking and that is ok because even with a great product, you can’t please everyone’s tastes.